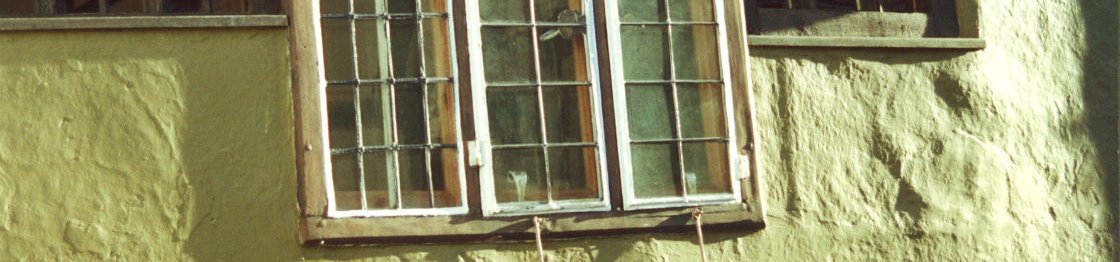

Metal windows

Old metal-framed windows can be beautiful and form an intrinsic part of many historic buildings. The extent of their unnecessary replacement is still of concern to the SPAB. Even where they are apparently beyond repair, closer inspection can reveal opportunities for conservation. This article deals with problems ranging from draughts and distortion to damp and 'rust jacking'.

What are the types of old metal window?

Metal windows in old buildings are principally made from one of three materials: wrought iron, cast iron or mild steel. Their historical development reflects advancing technology.

Individually-crafted wrought iron frames with leaded glass date from the mid-16th century onwards and are of the fixed or opening casement type. Factory-made cast iron windows appeared in the mid-19th century, the sliding sash version becoming particularly popular. Components have a deeper profile and more repetitive appearance than wrought iron. Mild steel windows were produced extensively from the First World War to the 1970s. Synonymous with the dominant manufacturer, Crittall, they exist in a wide variety of styles and standard sizes.

What problems might arise with old metal windows?

Properly maintained, metal windows can last for centuries. When protective coatings are neglected, though, corrosion may occur. Ungalvanised steel windows (generally those pre-dating c1950) are most susceptible to rusting under these circumstances, though wrought and cast iron can also be affected. Corrosion leads to the loss of original material, staining on adjacent surfaces and, as the metal expands, cracked glass and split masonry at fixing points (the latter being termed ‘rust jacking’).

Other potential problems include the fracturing of cast iron because of impact or casting flaws, and the distortion of wrought iron or mild steel following forcible closure of casements where there is paint build-up.

How should I deal with rust on old metal windows?

Where exposure has resulted in the metal developing a stable protective surface, action will be unnecessary. Where deterioration continues, however, rust should be removed, taking care not to damage the glass or underlying sound metal. Light rust can be cleaned off manually or with power tools. More severely corroded windows frequently have to be taken to a workshop for treatment using acid pickling, air abrasives or, in the case of wrought iron, flame cleaning.

Bear in mind that wholesale cleaning will destroy all remnants of earlier, underlying paint schemes. Aim instead, therefore, to leave some evidence behind.

What other work may be needed to an old metal window other than rust removal?

Cleaning may reveal heavily corroded sections requiring repair. Wrought iron components can be repaired by cutting out defective lengths and welding in new pieces in the same material, as can steel members where the profiles are still available. Cast iron is most easily repaired by cold stitching. Specialist iron foundries can take moulds from cleaned originals and recast components.

Distorted frame members can usually be readily eased back to square. Stiff opening casements should be serviced to ensure proper operation first. All major work will, of course, entail prior removal of the glass.

How can I remedy a draughty old metal window?

First, service, ease and adjust the opening casements. If air leakage between the frame and casements is still a problem, this can be remedied by applying a silicone foam rubber sealant in the gap. The casement edges are temporarily lacquered or taped beforehand so that the sealant adheres only to the non-treated frame sides. Take care to select a non-corrosive sealant. To reduce condensation, allow for additional ventilation near sources of moisture.

Heavy curtains, insulated blinds, reused shutters and secondary glazing may be used additionally or as alternative methods

How should I go about redecorating old metal windows?

Paint selection depends, among other considerations, on site exposure and the historical interest of the building or surviving early paint finishes. Alkyd resin paints can be suitable. Micaceous iron oxide paints promise greater durability but are limited in colour range so may require overcoating. A common primer is zinc phosphate. Preparation is important. Care should be taken when rubbing down to minimize the risk from hazardous dust. Small areas of paint may be removed with chemical strippers.

English Heritage (2012) Metals, Practical Building Conservation, Farnham: Ashgate Publishing Ltd